OUR CAPABILITIES: REVOLUTIONIZING

THE FUTURE OF HIGH-DENSITY CIRCUITS

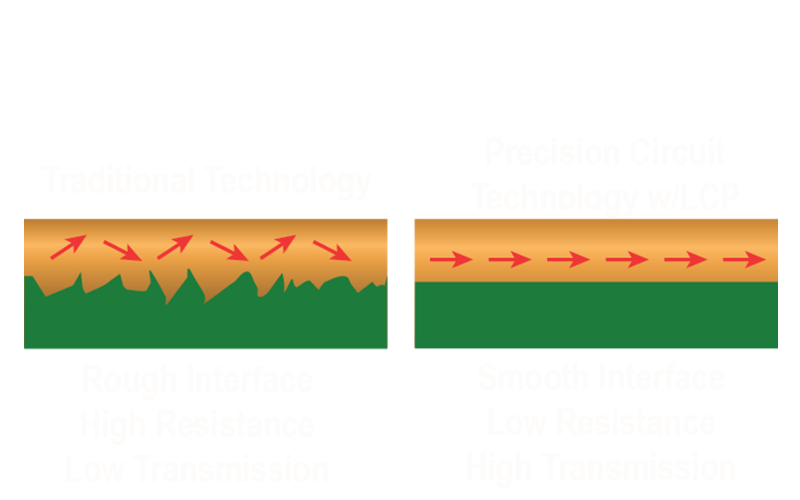

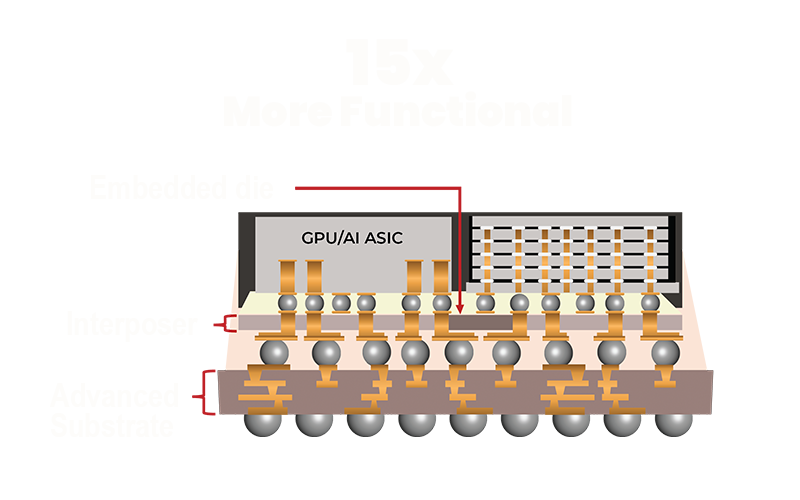

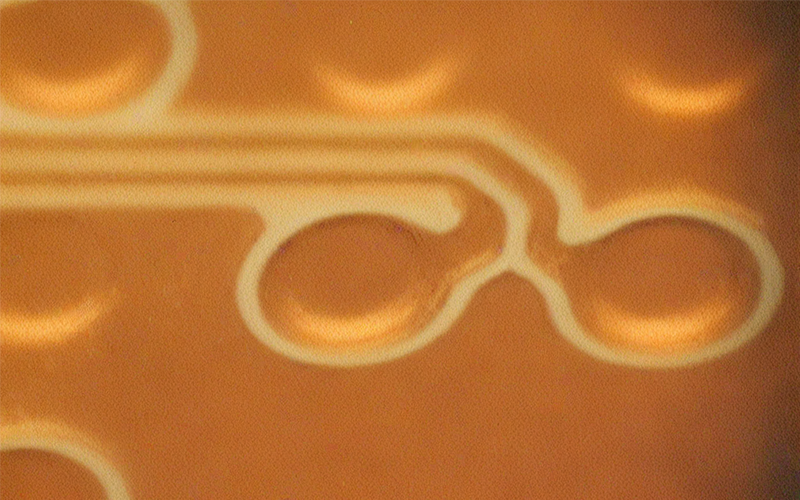

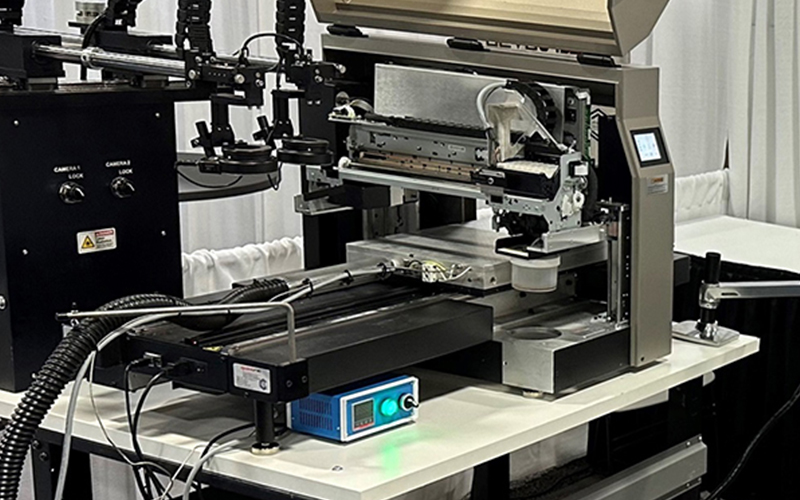

With an unwavering commitment to innovation, we are pushing the boundaries of what is possible in ultra high-density circuit design and fabrication. Our revolutionary approach not only advances UHDI circuit manufacturing but also provides engineers unprecedented design freedom and flexibility, empowering them to innovate in ways never before possible. We are privileged to share our expertise, capabilities and transformative methods, unlocking new possibilities for technological advancement.